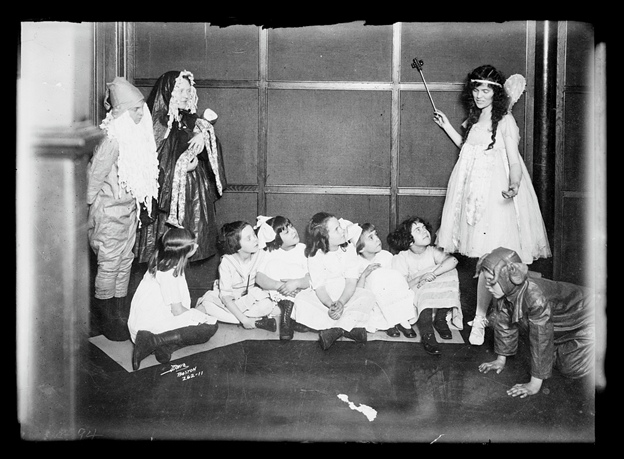

Source: US Library of Congress. This image is in the public domain. “Astra, Red Cross health fairy, brings gifts of health principles from the milky way to the juniors of the Prince School, Boston. The health fairy, who serves the Boston Metropolitan Chapter, is at the right, standing. Pupils of the school, members of the Junior Red Cross, who assisted her in a health play program given recently at the school, as they appear in the picture.” February 1922.

What’s new?

Inspired by Ray Dalio’s 2017 bestselling book Principles, performance coach Brad Stulberg put together his own list of principles as “a foundation for a better you.” Pocket brought it to my attention.

What does it mean?

A 2013 review of Jessica Lamb Shapiro’s book on the self-help industry in the United States, Promise Land, cites “an Ancient Egyptian genre called ‘Sebayt,’ an instructional literature on life (‘Sebayt’ means ‘teaching’)” as the “progenitor of self-help books.” I haven’t been in a bookstore for over a year, but I am sure that the self-help section at my local Barnes and Noble store still stretches over many shelves.

I haven’t read any of these books by Lamb Shapiro, Dalio, or Stulberg. For a description of the book by Ray Dalio, founder of investment firm Bridgewater Associates, I am relying heavily on this article by Elle McFarlane. She reviews the book’s contents and Dalio’s five principles, including “Use the 5-step process to get what you want out of life.” That process has five stages:

- Having clear goals

- Identifying the problems that prevent you from achieving these goals

- Getting to the root cause of these problems

- Designing plans to help you overcome these root causes

- Enforcing these plans to get your desired results .

Stulberg, inspired by Dalio, created a list of eight principles, including: Focus on the Process, Not Results (“Research shows that concentrating on the process is best for both performance and mental health”); Take Small, Consistent Steps to Achieve Big Gains (“Small and consistent victories compound over time, leading to massive gains”), and Make the Hard Thing Easier (“Rather than relying completely on self-control, intentionally design your environment to make the hard thing easier”).

When I taught the course Introduction to Industrial and Systems Engineering at Colorado State University-Pueblo for many years, I required students to read and report on a book, chosen from a list I provided or approved by me if not on the list. One of those books was The 7 Habits of Highly Effective People, by Stephen R. Covey. His seven habits include Habit 2: Begin With the End in Mind. “Habit 2 is based on imagination–the ability to envision in your mind what you cannot at present see with your eyes. It is based on the principle that all things are created twice. There is a mental (first) creation, and a physical (second) creation.”

What does it mean for you?

I am sure you have already noted that some of these personal principles echo strongly organizational principles. What works well for self-improvement also works for group-improvement.

I am an industrial engineer. My elevator speech to answer the question “what is industrial engineering?” is that industrial engineers are about efficiency, quality, and safety. We design the workplace so that ordinary people can achieve extraordinary results. Chapter 2 of the textbook I wrote for my introductory course lists “Big ideas you will hear frequently” and some of these ideas about industrial engineering could fit comfortably into any self-help list (“Small incremental improvements of a process add up, but more radical reengineering may sometimes be needed”).

Dalio’s five-step process is very similar to Six Sigma’s improvement cycle (Define, Measure, Analyze, Improve, and Control). Stulberg’s focus on the process is one of the core ideas of industrial engineering (in my book, I wrote: “The process for doing a task makes a big difference in how efficiently, well, and safely the task is done”). Taking small consistent steps is another way to describe continue improvement. Making Hard Things Easier is poke yoke or error-proofing. Many of these principles also take a systems view; for example, Dalio’s first principle is to understand reality.

What works well for self-improvement also works for group-improvement. Rather than relying on one of these gurus to provide you with a list of principles for how you want to act in your personal life and in your organization, I challenge you to learn from them (and many others) to create your own set of principles that you use to improve your personal life and your organization. What are your guiding principles for improvement of self and improvement of your organization?

Where can you learn more?

Of course there are many web pages that will give you advice on creating your principles or your core values and even lists of principles you can select from (101 Timeless Principles to Guide You to Your Best Life). For some reason, most lists of principles have an odd number of items (5, 7, 101), but Stulberg has 8. Make of that what you will.

Of course actions must reflect principles. As Patrick Lencioni wrote in 2002: “Enron—although an extreme case—is hardly the only company with a hollow set of values.”

Of course there is a contrary view: Why You Shouldn’t Be A Person Of Principle. Moral particularism points out that any set of ethical principles may seem fine. “But then you run into that odd, unexpected situation where following your rulebook doesn’t seem so neat and tidy. This new case is special, unique, and unanticipated by your ethical system. In fact, it just feels wrong to follow the rules here in this instance. Do you go with your rulebook, or your current intuition?” One of my guiding principles is: know the rules, choose which ones to follow, and live with the consequences.